Within the vast world of metalworking, the seemingly simple designation “DNGG 130504 ML” holds significant meaning for those in the know. This seemingly cryptic code represents a specific cutting tool from TaeguTec, a leading manufacturer of high-performance tools. This article delves deeper, exploring the breakdown of the code, the tool’s functionalities, and its potential applications within various machining operations.

Decoding the DNGG 130504 ML Code

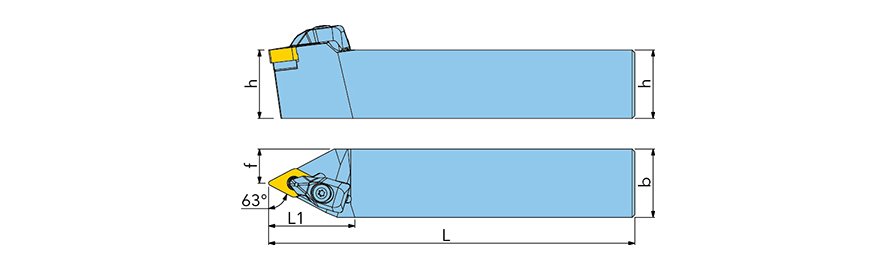

The DNGG 130504 ML code serves as a concise yet informative identifier for the cutting tool. Each segment conveys a specific characteristic:

- D – Insert type: The “D” indicates a negative insert style, a common design where the cutting insert sits within a dedicated pocket on the toolholder. This design offers benefits like easy insert replacement and improved chip control.

- NGG – Insert geometry: The “NGG” signifies a specific insert geometry. Without access to TaeguTec’s specific catalog information, it’s difficult to pinpoint the exact geometry details. However, “NGG” geometries are typically designed for general-purpose turning applications on various materials like steel and cast iron.

- 13 – Insert size: The “13” refers to the insert size, which impacts the cutting depth and toolholder compatibility. A larger number typically indicates a larger insert capable of handling deeper cuts.

- 05 – Corner radius: The “05” likely represents the corner radius of the cutting insert in millimeters (e.g., 0.5mm). The corner radius influences chip formation, surface finish, and tool life.

- 04 – Cutting edge length: The “04” most likely signifies the cutting edge length of the insert in millimeters (e.g., 4mm). This dimension affects the feed rate and overall machining efficiency.

- ML – Material grade: The “ML” denotes the specific material grade of the cutting insert. Again, without access to TaeguTec’s catalog, the exact material properties are unclear. However, “ML” grades are often formulated for optimal performance on a range of steel materials.

Understanding the Importance of Decoding:

By understanding this code breakdown, machinists can select the appropriate DNGG 130504 ML tool for their specific needs. Considering factors like material type, desired cutting depth, and required surface finish ensures optimal tool performance and efficient machining operations.

Applications of the DNGG 130504 ML Tool

Given the general-purpose nature of the NGG geometry and the ML material grade (likely suitable for steel), the DNGG 130504 ML tool is likely well-suited for various turning applications, including:

- Roughing: Initial machining passes to remove large amounts of material efficiently.

- Finishing: Creating a smooth and precise final surface finish on the workpiece.

- Facing: Machining a flat surface perpendicular to the lathe axis.

- Grooving: Creating precise grooves or channels on the workpiece.

- Chamfering: Creating beveled edges on the workpiece for aesthetic or functional purposes.

Beyond the Basics: Optimizing Performance

While the DNGG 130504 ML offers a versatile solution, maximizing its performance requires considering additional factors:

- Machine capabilities: Ensure the lathe or machining center has sufficient horsepower and spindle speed to handle the chosen cutting tool and material combination.

- Cutting parameters: Select appropriate cutting speed, feed rate, and depth of cut based on the material, tool specifications, and desired results. Refer to TaeguTec’s recommendations or industry standards for guidance.

- Coolant selection and application: Utilizing the appropriate coolant type and directing it effectively at the cutting zone optimizes chip formation, reduces heat generation, and extends tool life.

- Workholding: A secure and rigid workholding setup minimizes vibration and ensures machining accuracy.

TaeguTec: A Renowned Name in Cutting Tools

Founded in 1988, TaeguTec has established itself as a global leader in the cutting tool industry. They are known for:

- Innovation: Continuously developing new cutting tool materials, geometries, and coatings to enhance machining efficiency and productivity.

- Quality: Maintaining strict quality control measures to ensure consistent performance and tool life.

- Customer support: Providing extensive technical support and application assistance to customers.

By leveraging the DNGG 130504 ML tool’s capabilities and partnering with a reputable brand like TaeguTec, machinists can achieve superior results in their turning.

Benefits of DNGG 130504 ML Cutting Inserts

The DNGG 130504 ML insert boasts several advantages that can enhance your machining operations:

- Improved Machining Performance:

- The insert geometry and coating are designed for specific machining applications, leading to:

- Enhanced chip control: Optimized chip formation reduces chip buildup, minimizing tool wear and improving surface finish.

- Reduced cutting forces: The insert design allows for efficient metal removal, minimizing machine load and extending tool life.

- Increased productivity: Faster cutting speeds and longer tool life translate to higher production output.

- The insert geometry and coating are designed for specific machining applications, leading to:

- Material Versatility: The DNGG 130504 ML might be suitable for a variety of materials depending on the specific grade and coating. This could include:

- Steels (mild, alloy, stainless)

- Cast iron

- Aluminum alloys

- Certain plastics

- Cost-Effectiveness:

- The insert’s extended tool life translates to fewer insert changes, reducing overall machining costs.

- Improved machining performance translates to faster production times, potentially lowering labor costs.

- Standardized Design: The DNGG format is a commonly used insert geometry, ensuring compatibility with various tool holders and machining centers. This simplifies tool selection and inventory management.

Additional Considerations for Specific Benefits:

- Consult the TaeguTec catalog or technical support: To maximize the benefits of the DNGG 130504 ML, identify the specific insert grade and coating best suited for your material and machining application.

- Utilize appropriate cutting parameters: Factors like cutting speed, feed rate, and depth of cut significantly impact performance. Refer to TaeguTec’s recommendations or conduct machining trials to optimize these parameters for your specific setup.

Safety Considerations for Using DNGG 130504 ML Inserts

While the DNGG 130504 ML offers numerous benefits, prioritizing safety is paramount. Here are key safety considerations:

-

Proper Machine Setup:

- Ensure the machine tool is in good working order and properly maintained.

- Securely mount the cutting tool holder and verify correct insert orientation and clamping.

- Utilize appropriate safety guards and enclosures to minimize exposure to flying chips or debris.

- Set cutting parameters within the recommended range for the insert and machine tool.

-

Personal Protective Equipment (PPE):

- Always wear safety glasses or a face shield to protect your eyes from flying chips.

- Utilize appropriate gloves to protect your hands from sharp edges and hot materials.

- Hearing protection may be necessary depending on the noise level during machining operations.

-

Safe Work Practices:

- Never reach into the machining area while the machine is running.

- Ensure proper chip evacuation to prevent chip buildup and potential tool breakage.

- Be aware of your surroundings and maintain a safe distance from the machine while it’s operational.

- Follow proper procedures for tool changes and disposal of used inserts.

Additional Safety Tips:

- Training and Awareness: Machinists using the DNGG 130504 ML inserts should receive proper training on safe machining practices specific to the application and machine tool.

- Material Safety Data Sheets (MSDS): Always familiarize yourself with the safety hazards of the material being machined and follow appropriate precautions.

By adhering to these safety considerations, you can minimize risks and ensure the safe and effective operation of the DNGG 130504 ML cutting inserts in your machining processes.