Hardinge G32 Code machines are renowned for their precision and versatility in machining. In this guide, we will take a deep dive into the Hardinge G32 code. This G-code is specifically used for thread cutting operations on CNC (Computer Numerical Control) machines. Whether you’re an experienced machinist or someone new to CNC programming, this article will help you understand the G32 code inside and out, providing you with a thorough guide on its application, syntax, benefits, and more.

1. Introduction to G-codes in CNC Machining

G-codes form the foundation of CNC machining. They are instructions that guide the machine on how to move, what actions to perform, and the specific dimensions to follow. Each G-code is unique and serves a specific purpose, such as positioning, cutting, drilling, and threading.

In the world of CNC programming, precision and accuracy are crucial. This is why machinists and programmers rely on Hardinge G32 Code to execute specific functions like thread cutting with high precision.

Key Takeaway:

G-codes enable precise control over CNC machines, ensuring that parts are machined to exact specifications.

2. What is Hardinge G32 Code?

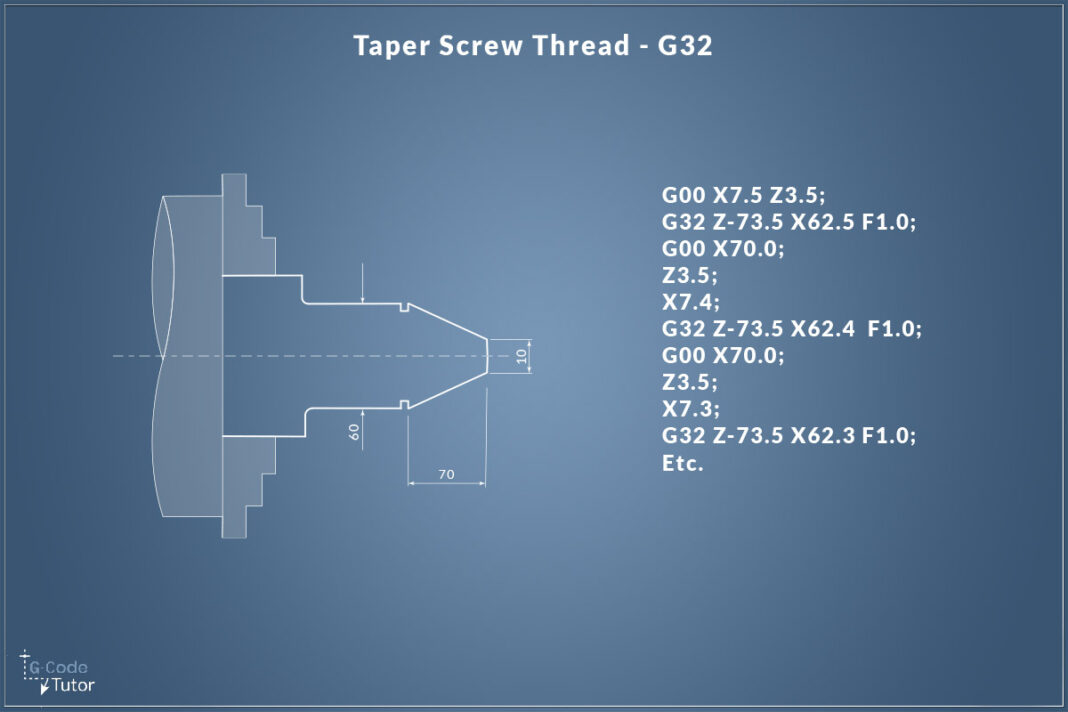

The Hardinge G32 Code is specifically designed for thread cutting operations. Thread cutting involves cutting a helical groove (thread) on cylindrical or conical surfaces, such as screws or bolts. The G32 code instructs the CNC lathe to cut a thread along the Z-axis while maintaining synchronization with the spindle rotation.

Unlike other thread-cutting methods, the G32 code does not automate the return path or cycle, meaning the operator has more manual control over the process. This makes G32 ideal for machinists who need customization or specific threading patterns.

Key Takeaway:

Hardinge G32 Code is essential for performing precise thread-cutting operations on a CNC machine.

3. Syntax of the Hardinge G32 Code

Understanding the syntax of the G32 code is crucial for its correct application. The basic format of the G32 command is as follows:

G32 X[Diameter] Z[Length] F[Feed Rate]

Parameter Breakdown:

- X: Defines the diameter of the part being threaded.

- Z: Indicates the length of the thread along the Z-axis.

- F: Specifies the feed rate (or thread pitch), determining the spacing between threads.

This basic structure allows the machinist to define the exact dimensions and parameters for the threading operation.

Example of G32 Code:

G32 X20.0 Z-40.0 F2.0

This example would instruct the machine to cut a thread along the Z-axis with a diameter of 20.0mm, a length of 40.0mm, and a feed rate of 2.0mm per revolution.

Key Takeaway:

Proper syntax is essential for successfully using the G32 code to cut threads.

4. Parameters in the G32 Code

The Hardinge G32 code utilizes several parameters to ensure precise thread cutting. Here’s a closer look at the key parameters:

- X (Diameter): Defines the outside diameter of the part where the thread is being cut. This is the starting diameter for external threading and ending diameter for internal threading.

- Z (Length): The total distance the thread is to be cut along the Z-axis. It’s essential to calculate this value precisely, as incorrect lengths can lead to faulty threading.

- F (Feed Rate): Also known as thread pitch, this defines the distance the tool advances for each spindle revolution. The feed rate needs to match the thread size, ensuring even spacing between each thread.

Accurate parameter input is crucial to achieving the desired thread pattern and avoiding machine errors.

Key Takeaway:

Precision in entering parameters such as diameter, length, and feed rate ensures accurate thread cutting.

5. Applications of Hardinge G32 Code

The G32 code is used in various industrial applications, particularly in sectors where precise threading is essential. Some common applications include:

- Automotive Manufacturing: Producing threaded bolts, screws, and other fasteners.

- Aerospace Industry: Machining parts that require precise and durable threading.

- General Machining: Creating threaded components for a wide range of industries, from construction to electronics.

G32 is invaluable in any application requiring customized or precise threading.

Key Takeaway:

The G32 code is widely used in industries that demand accurate and customized threading solutions.

6. Advantages of Using G32 Code in CNC Programming

The G32 code offers several key advantages in CNC thread cutting:

- Customization: The manual control over each threading cycle provides machinists with the ability to create custom threading patterns.

- Precision: G32 allows for highly accurate thread cutting, especially when threading complex parts.

- Versatility: This code can be used for both internal and external threading, making it adaptable to various machining tasks.

With these benefits, G32 remains one of the most reliable codes for thread cutting operations.

Key Takeaway:

The G32 code is essential for achieving high precision and customization in thread cutting operations.

7. Step-by-Step Process for Using G32 Code

Let’s go through a typical process for using the G32 code in a CNC machine:

- Preparation:

- Load the part to be threaded into the CNC machine.

- Set the work coordinate system (WCS) using G54 or G55.

- Programming the G32 Code:

- Input the dimensions of the part, including the diameter and thread length.

- Enter the G32 code with appropriate parameters.

- Running the Code:

- Start the machine, ensuring the spindle speed is synchronized with the feed rate.

- Monitor the threading process, adjusting parameters if necessary.

- Final Inspection:

- Once the thread is cut, inspect the part using thread gauges or calipers to ensure accuracy.

Key Takeaway:

Follow a structured process for using G32 to ensure accurate and reliable thread cutting.

8. Best Practices for Thread Cutting Using G32 Code

When working with the G32 code, following best practices will help avoid errors and ensure a smooth operation. Here are some tips:

- Synchronize Spindle Speed and Feed Rate: Ensuring proper synchronization will result in even and accurate threads.

- Double-Check Parameters: Before running the code, verify the X, Z, and F values to prevent any discrepancies.

- Use Proper Tooling: Ensure that the cutting tools are sharp and properly set up to reduce tool wear and maintain thread precision.

Key Takeaway:

Adopting best practices like double-checking parameters and using the correct tools can prevent errors during thread cutting.

9. Common Mistakes to Avoid While Using G32 Code

While the G32 code is powerful, it can lead to issues if not used correctly. Some common mistakes include:

- Incorrect Feed Rate: Using the wrong feed rate can result in uneven threads or tool breakage.

- Improper Tool Alignment: If the threading tool isn’t aligned correctly, it can cause thread pitch errors or damage to the part.

- Overlooking Machine Calibration: Machines must be properly calibrated before performing threading operations. Failing to do so may cause inaccuracies.

By avoiding these common mistakes, you can achieve high-quality thread cuts every time.

Key Takeaway:

Avoid common errors like incorrect feed rates and improper tool alignment to ensure smooth and precise threading operations.

10. Troubleshooting Issues with Hardinge G32 Code

Despite careful planning, issues may arise when using the Hardinge G32 Code. Here’s how to troubleshoot some common problems:

- Thread Misalignment: Recheck your spindle synchronization and tool alignment. Adjust the feed rate if necessary.

- Tool Breakage: If the tool is breaking frequently, it could indicate excessive wear or an incorrect cutting speed.

- Inconsistent Thread Pitch: Ensure that the machine settings, especially the feed rate, match the thread requirements.

Key Takeaway:

Effective troubleshooting of common issues like thread misalignment and tool breakage ensures a smooth operation.

11. Conclusion: Mastering G32 Code for Thread Cutting Operations

Mastering the Hardinge G32 code is crucial for anyone involved in CNC machining, especially in industries that require precise thread cutting. By understanding the syntax, applications, and common issues, you can optimize your CNC processes and ensure accurate and high-quality threading results.

This guide serves as a comprehensive resource for getting the most out of the Hardinge G32 Code, enabling you to cut threads with confidence and precision.