The Z16 Perforated Zee picture is an innovative structural component widely used across industries for its versatility, durability, and unique design. Its perforated pattern and “Zee” shape make it ideal for both architectural and industrial applications. Whether for ventilation, lightweight structural support, or aesthetic purposes, the Z16 Perforated Zee picture stands out as a reliable solution.

In this article, we will explore the details of Z16 Perforated Zee picture, covering its features, common uses, benefits, installation methods, and frequently asked questions to provide a comprehensive understanding of this remarkable component.

What Is the Z16 Perforated Zee picture?

The Z16 Perforated Zee picture is a metal profile with a Z-shaped cross-section, designed with uniform perforations along its length. It is typically manufactured from high-strength materials such as galvanized steel, stainless steel, or aluminum, ensuring excellent durability while maintaining a lightweight structure.

The Z16 designation refers to its specific dimensions and perforation pattern, making it compatible with diverse applications where airflow, drainage, or design aesthetics are crucial.

Key Features of Z16 Perforated Zee picture

The Z16 Perforated Zee picture comes with a range of features that enhance its usability and performance. Below are some of the standout characteristics:

1. Perforated Design

The perforations ensure optimal air circulation and drainage, making it suitable for applications requiring ventilation or moisture control.

2. Zee Shape

Its “Zee” cross-sectional design provides structural stability while maintaining a lightweight profile. This design is particularly advantageous for load-bearing applications.

3. Corrosion Resistance

When made of materials such as galvanized steel or stainless steel, the Z16 Perforated Zee picture exhibits excellent resistance to rust and corrosion, even in harsh environments.

4. Customizability

Manufacturers often provide customizable options for perforation size, material thickness, and length, ensuring the product meets specific project requirements.

5. Ease of Installation

The lightweight nature of the Z16 Perforated Zee makes it easy to handle, transport, and install, reducing labor costs and installation time.

Applications of Z16 Perforated Zee

The versatility of the Z16 Perforated Zee makes it suitable for a wide range of applications across industries. Some of its common uses include:

1. Construction and Architecture

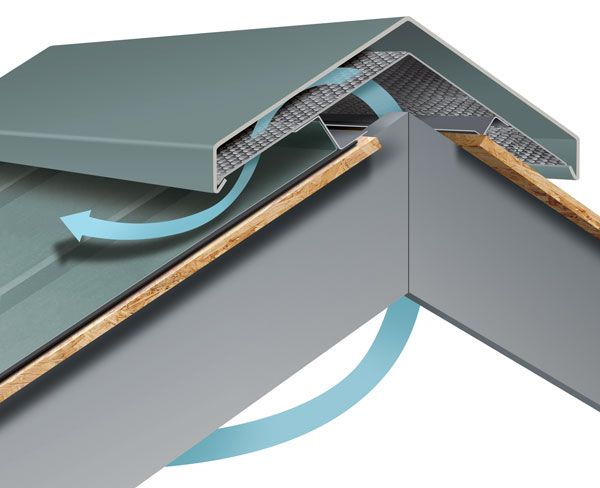

- Ventilated Cladding: Used as part of external cladding systems to allow airflow while providing structural support.

- Decorative Panels: Adds aesthetic appeal to buildings with its unique perforated design.

- Partition Walls: Lightweight yet sturdy partitions in commercial or industrial spaces.

2. Industrial Settings

- Cable Management: Ideal for organizing and supporting cables in industrial facilities.

- Machine Guards: Provides safety without compromising visibility or ventilation.

- Storage Solutions: Used in shelving and racks due to its load-bearing capacity and lightweight nature.

3. HVAC Systems

- Facilitates ventilation and air distribution in HVAC systems, ensuring efficient airflow without obstructing structural stability.

4. Automotive and Transportation

- Lightweight Frames: Used in vehicle components for reduced weight and enhanced fuel efficiency.

- Drainage Systems: Ensures water drainage in transportation infrastructure like bridges and railways.

Advantages of Using Z16 Perforated Zee

The Z16 Perforated Zee offers numerous benefits, making it a preferred choice in various applications. Below are the key advantages:

1. Enhanced Ventilation

The perforated design ensures unobstructed airflow, making it ideal for applications requiring air circulation or cooling.

2. Lightweight and Strong

Despite its lightweight nature, the Z16 Perforated Zee provides exceptional strength and stability, reducing the overall weight of structures without compromising integrity.

3. Corrosion Resistance

Durable materials such as galvanized or stainless steel ensure a long lifespan, even in challenging environments.

4. Aesthetic Appeal

Its perforated design adds a modern, industrial look to architectural projects, enhancing visual appeal.

5. Cost-Effective

The combination of lightweight material, easy installation, and durability makes the Z16 Perforated Zee a cost-efficient choice for various projects.

Installation of Z16 Perforated Zee

Proper installation is crucial to maximizing the performance and durability of the Z16 Perforated Zee. Here are the key steps:

1. Preparation

- Measure and cut the Z16 Perforated Zee to the required dimensions.

- Ensure the surface is clean and free of debris.

2. Attachment

- Use screws, bolts, or rivets to attach the Zee to the desired surface or frame.

- Align the perforations to ensure proper airflow or drainage, if required.

3. Reinforcement

- For load-bearing applications, ensure proper spacing and secure connections to prevent structural failure.

4. Finishing

- Apply protective coatings, such as paint or powder coating, to enhance durability and match the design aesthetics.

Maintenance Tips for Z16 Perforated Zee

To ensure the Z16 Perforated Zee remains functional and visually appealing, regular maintenance is essential. Here are some tips:

- Cleaning: Periodically clean the perforations to remove dust, debris, or grime.

- Inspection: Check for signs of wear, rust, or damage, especially in outdoor applications.

- Protective Coating: Reapply protective coatings if necessary to maintain corrosion resistance.

Frequently Asked Questions (FAQs)

1. What materials are used for Z16 Perforated Zee?

The Z16 Perforated Zee is commonly made from galvanized steel, stainless steel, or aluminum, offering varying levels of strength, corrosion resistance, and weight.

2. Can the perforation size be customized?

Yes, many manufacturers offer customizable options for perforation size, spacing, and pattern based on specific project requirements.

3. Is Z16 Perforated Zee suitable for outdoor use?

Absolutely! When made from corrosion-resistant materials like stainless steel or galvanized steel, it performs well in outdoor environments.

4. What industries benefit most from Z16 Perforated Zee picture?

The Z16 Perforated Zee picture is widely used in construction, architecture, HVAC systems, industrial applications, and transportation infrastructure.

5. How is the Z16 Perforated Zee picture different from other perforated profiles?

Its unique Zee shape and specific perforation pattern provide superior strength, ventilation, and versatility compared to standard flat or U-shaped perforated profiles.

Conclusion

The Z16 Perforated Zee is a versatile and cost-effective solution for numerous applications, ranging from architectural designs to industrial settings. Its perforated design, combined with a lightweight yet strong structure, ensures optimal performance in ventilation, drainage, and load-bearing applications. Whether you’re looking to enhance the aesthetics of a building or improve the efficiency of an HVAC system, the Z16 Perforated Zee delivers exceptional value.

By understanding its features, applications, and benefits, you can confidently integrate the Z16 Perforated Zee into your next project. With proper installation and maintenance, this innovative component will serve as a durable and reliable solution for years to come.