In the world of bioprocessing and pharmaceutical research, precise control over fluid dynamics is essential. Repligen Minikros Flow Rate, a leader in life sciences and bioprocessing technology, has introduced the Minikros™ system, which revolutionizes fluid management in laboratory and production settings. Among its key features is its impressive flow rate capabilities, making it an invaluable tool for a wide range of applications, from protein purification to viral vector manufacturing. This article dives deep into the Repligen Minikros Flow Rate, its significance, applications, and how it supports the bioprocessing industry’s growing demands.

What is Repligen Minikros Flow Rate?

The Repligen Minikros Flow Rate system is an advanced, high-performance flow path designed for precise, scalable fluid management. This system is often used in conjunction with tangential flow filtration (TFF) for applications such as concentration, diafiltration, and purification processes. It is known for its accuracy, reliability, and efficiency, enabling both research and commercial operations to streamline their processes.

The Minikros system is part of a broader lineup of technologies offered by Repligen Minikros Flow Rate which focuses on enabling faster, more efficient bioprocessing for companies in biotechnology, pharmaceuticals, and life sciences. The system’s flow rate is one of its standout features, allowing users to fine-tune their processes with ease.

Key Features of Repligen Minikros Flow Rate

Understanding the features of the Minikros system provides valuable insights into its flow rate capabilities and how they contribute to the system’s overall effectiveness. Some of the standout features include:

1. Precision Flow Control

The flow rate is a critical aspect of any filtration or bioprocessing operation. Minikros offers highly precise control over flow rate, allowing users to customize their processes according to the specific requirements of the fluid being processed. Whether it’s a small-scale lab experiment or large-scale industrial production, Minikros ensures that fluids move at the optimal rate for each step.

2. Scalable Solutions

The Minikros system is designed to provide scalable solutions that grow with the needs of the user. This flexibility is essential in industries like biotechnology, where production volumes may increase rapidly as a product moves from research to commercialization. The ability to scale the flow rate ensures that systems remain efficient and accurate at both small and large scales.

3. Versatile Compatibility

Minikros systems are compatible with various filtration devices and accessories, including Repligen Minikros Flow Rate proprietary TFF modules. This versatility enhances the system’s overall utility and allows for seamless integration into existing bioprocessing workflows. By offering high flow rates and precise control, the Minikros system enables operators to manage a variety of fluid types, from cell cultures to complex biochemical solutions.

4. Enhanced Productivity

The Repligen Minikros Flow Rate system helps boost productivity by improving throughput and reducing downtime. By offering consistent and predictable flow rates, the system allows bioprocessors to focus on other critical aspects of their workflow, improving overall operational efficiency. Moreover, the accurate flow rate control minimizes the need for reprocessing, reducing time and labor costs.

5. Built-in Monitoring Capabilities

Minikros integrates real-time monitoring of flow rate, pressure, and other critical parameters. This built-in monitoring ensures that operators have access to up-to-date information on their processes, allowing them to make informed decisions and prevent issues such as clogging or suboptimal performance.

Understanding Flow Rate in the Context of Bioprocessing

Repligen Minikros Flow Rate refers to the amount of fluid passing through a system in a given period. In the context of bioprocessing, the flow rate plays a pivotal role in various operations, particularly in filtration and purification processes like TFF.

The Repligen Minikros Flow Rate system’s ability to control flow rates with such precision makes it ideal for bioprocessing. Here are some of the key reasons why flow rate is critical in this industry:

1. Impact on Filtration Efficiency

In operations like TFF, the flow rate directly influences the efficiency of the filtration process. Too high a flow rate could lead to incomplete filtration, while too low a rate might increase processing time. The ability to adjust the flow rate ensures that the filtration process remains effective, whether concentrating proteins or removing impurities.

2. Influence on Protein Purification

Protein purification is a key application in bioprocessing, and flow rate can significantly affect yield and purity. By optimizing the flow rate, operators can ensure that proteins are efficiently separated from contaminants, leading to higher-quality output with fewer losses.

3. Effects on Process Consistency

Consistency is critical in bioprocessing, especially for products that will later undergo clinical trials or commercial production. Accurate control over flow rate ensures that each batch is processed consistently, minimizing variability and ensuring product quality.

4. Reducing Shear Stress

In bioprocessing, shear stress caused by high fluid velocities can damage delicate molecules like proteins and cells. The Minikros system offers adjustable flow rates that allow operators to minimize shear stress, helping to preserve the integrity of sensitive compounds during processing.

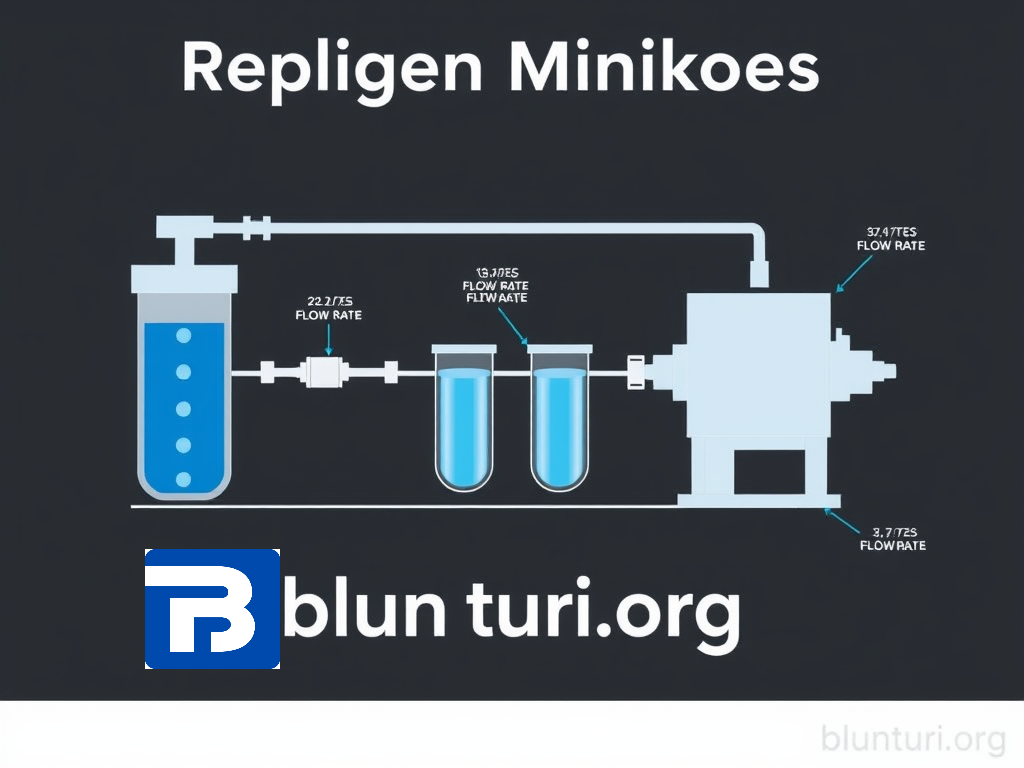

Minikros Flow Rate Specifications

The flow rate range offered by the Minikros system varies depending on the model and configuration. However, one of the key selling points of the system is its ability to offer a wide range of flow rates that can be tailored to the specific needs of the user. Typical flow rate specifications include:

- Low Flow Rates: Ideal for small-scale laboratory work, where precision and control are paramount. These lower flow rates enable users to perform small batch runs with accuracy.

- Medium Flow Rates: Suitable for pilot-scale production and medium-volume processing. This range strikes a balance between precision and speed.

- High Flow Rates: Used for large-scale production, these flow rates allow for faster processing and higher throughput, making them ideal for industrial-scale applications.

Applications of Minikros Flow Rate in Bioprocessing

The Repligen Minikros Flow Rate is integral to a variety of applications in bioprocessing. Below are some of the key areas where precise flow rate control can have a significant impact:

1. Tangential Flow Filtration (TFF)

TFF is a critical technique used in bioprocessing for concentration, clarification, and diafiltration. The Minikros system’s precise flow rate control makes it an essential tool for achieving the desired results in TFF, whether in laboratory, pilot, or industrial-scale operations. Accurate flow rates help optimize filter performance, minimize fouling, and increase yield.

2. Protein Purification

Protein purification often requires multiple filtration and separation steps. The ability to control flow rate ensures that each step is optimized for maximum efficiency, allowing bioprocessors to achieve high-purity proteins with minimal losses. Whether for therapeutic protein production or research purposes, the Minikros system plays a crucial role in streamlining protein purification workflows.

3. Viral Vector Production

Viral vectors are used in gene therapy and vaccine development, and their production requires highly controlled conditions to ensure both safety and efficiency. The Minikros flow rate control system ensures that viral vectors are processed effectively, with minimal risk of contamination or yield loss.

4. Cell Culture Processing

Cell cultures are a cornerstone of biotechnology, and maintaining the right flow rate during harvesting and processing is essential to preserving cell integrity. Minikros allows for controlled flow rates, reducing shear stress and enabling better handling of cells during critical stages of the bioprocess.

5. Biopharmaceutical Manufacturing

The biopharmaceutical industry relies on consistent and efficient production methods to meet global demand. The ability to precisely manage flow rates within the Minikros system supports all aspects of biopharmaceutical manufacturing, from upstream processes like fermentation to downstream purification and final product recovery.

Why Choose Repligen Minikros Flow Rate for Your Bioprocessing Needs?

Repligen Minikros Flow Rate offers several advantages over traditional systems, making it the preferred choice for many bioprocessing professionals:

1. Proven Technology

With years of industry expertise, Repligen Minikros Flow Rate has built a reputation for reliability and precision. Minikros benefits from this legacy, offering users a robust, tried-and-tested solution for their bioprocessing workflows.

2. Ease of Use

Repligen Minikros Flow Rate systems are designed to be user-friendly, with simple controls and intuitive interfaces that make setup and operation seamless. This ease of use allows operators to focus on their primary tasks without being bogged down by complex machinery.

3. High Performance

Whether you’re running a small lab experiment or large-scale commercial production, the Minikros system offers high performance across all stages of the bioprocess. Its ability to manage flow rates precisely and efficiently leads to faster results and reduced risk of error.

4. Cost-Effective Solution

By reducing the need for reprocessing, minimizing downtime, and improving overall efficiency, Minikros helps lower operational costs, making it a cost-effective choice for bioprocessors looking to maximize their investment.

5. Customization Options

Repligen Minikros Flow Rate provides options for customizing the Minikros system to meet the specific needs of each user. Whether you’re working with small volumes or high-throughput production, the system can be tailored to fit your exact requirements.

Conclusion

Repligen Minikros Flow Rate system, with its advanced flow rate control capabilities, is an indispensable tool for bioprocessing professionals. By offering precision, scalability, and versatility, the system empowers users to optimize their operations, whether in research, development, or industrial production. Whether you’re involved in protein purification, viral vector production, or any other bioprocessing task, Minikros provides the reliability and performance you need to stay ahead of the curve in this rapidly evolving industry.

As the bioprocessing sector continues to grow, the Minikros system will play a crucial role in ensuring that fluid management remains efficient, scalable, and cost-effective. For those looking to enhance their bioprocessing workflows, understanding the importance of flow rate control in systems like Minikros is a step toward achieving greater success and delivering high-quality products to market faster.