Understanding Rigid Casters

Rigid casters, sometimes called fixed casters, are wheel assemblies mounted in a non-swiveling configuration. This straightforward design ensures that platforms or carts can move smoothly in a straight path, making them ideal for controlled transport of items over set routes. By integrating a rigid caster wheel, businesses can significantly improve the stability and control of existing carts and equipment, especially when handling heavy loads.

The primary advantage rigid casters offer over swivel options is their enhanced stability under load. This makes them perfect for industrial settings where heavy-duty performance is paramount. With less risk of drifting or sudden changes in direction, operators benefit from safer navigation, reduced workplace accidents, and more predictable performance.

Before retrofitting, it’s important to understand your cart or platform’s operational environment. Consider pathways, the required turning radius, and the nature of loads typically transported. Rigid casters thrive in situations requiring straightforward, repeatable movement rather than frequent direction changes.

Assessing Your Platform or Cart

Proper planning prevents costly retrofitting mistakes. Start by thoroughly evaluating the structural integrity of your platform or cart. Focus on three key areas:

- Weight Capacity:Identify the maximum load, including the platform weight and all cargo. Overlooking this step is a frequent cause of caster failure in real-world operations.

- Material Composition:Robust metal, hardwood, or reinforced plastic platforms generally provide a sound mounting surface. Avoid areas with rot, rust, or damage as these may compromise safety.

- Surface Compatibility:The type of flooring—concrete, epoxy-coated, tile, or carpeted—will influence ideal wheel material. Hard floors work well with soft wheels, while soft floor surfaces require hard wheel materials to prevent excess wear.

Factoring in floor transitions or inclines is also vital. Platforms, trailing ramps, or door thresholds may require specialized wheels or bracing for extra stability.

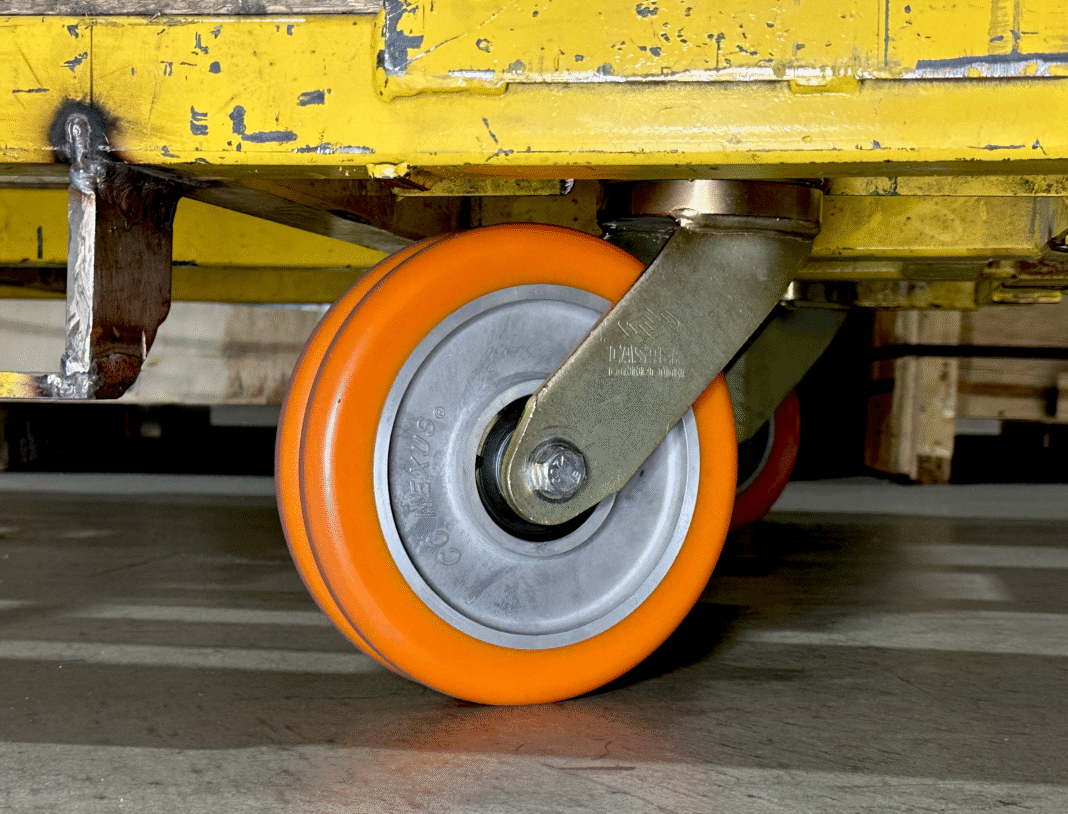

Choosing the Right Rigid Casters

Not all rigid casters are created equal. When upgrading your existing equipment, consider the following:

- Load Capacity:Divide the total expected weight by the number of casters to determine the minimum requirement per caster. Always round up for a safety margin.

- Wheel Material:Steel, polyurethane, and nylon offer durability, but may leave marks or damage on some surfaces. Rubber wheels are gentler on flooring but can wear faster.

- Mounting Type:Plate-mounted casters distribute weight over a larger area and are preferable for heavier loads. Stem-mounted casters work well with lighter or modular platforms but require compatible sockets for secure attachment.

Checking for compatibility with your mounting surface before purchase prevents installation delays and ensures lasting performance.

Installation Process

Preparation and Marking

Before mounting new casters, remove any loads and thoroughly clean the underside of your platform. Position the casters, usually at or near each corner, and precisely mark the bolt-hole locations for drilling. Accurate positioning ensures even load distribution and prevents misalignment.

Drilling and Attachment

Use the correct drill bit size to make holes corresponding to your caster’s mounting plate. Please attach it to the recommended grade hardware (typically Grade 5 or higher for industrial use) and tighten it securely according to manufacturer specifications. Avoid overtightening, which can stress the mounting surface or hardware.

Testing the Platform

With casters in place, conduct several trial runs—first empty, then with incremental loading. Ensure straight, stable rolling and double-check all fasteners after initial tests to confirm security.

Common Challenges and Solutions

- Uneven Load Distribution:Disproportionate loading may cause casters to wear prematurely or lead to platform tipping. Even distribution is paramount—adjust cargo placement and choose reinforced casters as needed.

- Floor Damage:Match the wheel material to your floor type to prevent surface scuffing. Consider adding wheel covers or mats at transition points.

- Increased Height:Retrofitting often raises platform height, which can introduce ergonomic concerns. Use adjustable or low-profile casters to minimize the impact, ensuring comfortable and safe use by staff.

Maintenance Tips

Scheduled maintenance keeps casters operating at peak efficiency.

- Inspection:Look for flattened, cracked, or wobbly wheels and check that all nuts and bolts remain tight.

- Cleaning:Debris, string, or packing material can jam wheels. Clear these regularly for smooth, safe function.

- Lubrication:Grease the axle and bearings periodically. This prevents squeaks and eases strain on moving parts, especially in high-use environments.

Establish a routine inspection schedule and keep a maintenance log to track issues, replacement cycles, and adjustments.

Innovative Solutions

Technological advancements make it easier than ever to upgrade mobility on older platforms. Motorized caster units like the Drive Caster® combine movement precision with power assistance. These all-in-one modules include their own drive mechanism, simplifying retrofits and reducing the need for manual pushing. Such features are especially effective for medical equipment, warehouse carts, or mobile production fixtures in demanding environments.

Incorporating powered movement options expands operational flexibility and reduces physical strain on staff, supporting both safety and productivity.

Final Thoughts

Upgrading existing platforms or carts with rigid casters is a straightforward way to boost workplace efficiency and safety. A methodical approach to assessment, selection, installation, and ongoing maintenance ensures long-lasting functionality and smooth operation. Stay attuned to innovations in caster design to future-proof your operations and accommodate evolving facility demands.